For over 100 years, Stanadyne has been creating innovative solutions to the world’s most challenging problems.

start

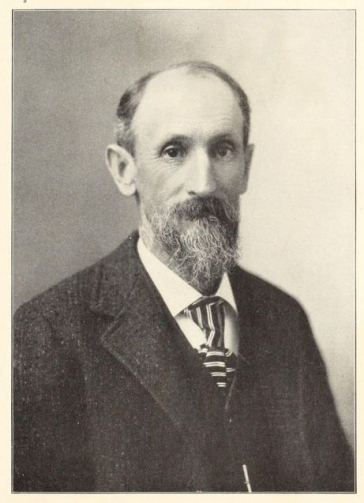

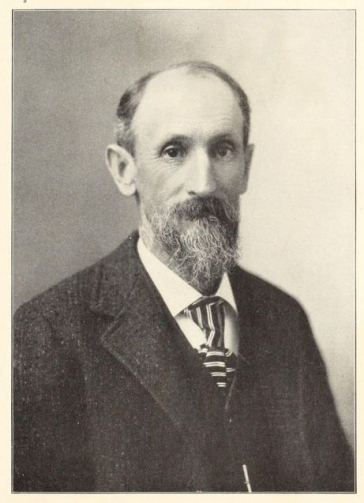

Christopher Spencer invents the automatic screw machine; thus, Hartford Machine Screw Company is born.

1934

To begin building a reputation as a design and engineering focused company, Hartford Machine Screw Company merges with its affiliates to form Standard Screw.

1947

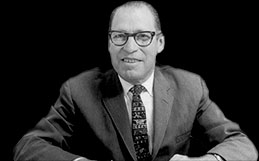

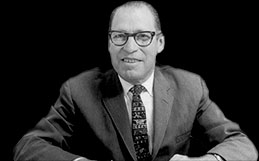

Vernon D. Roosa joins Standard Screw to perfect his design for an on-engine diesel pump.

1952

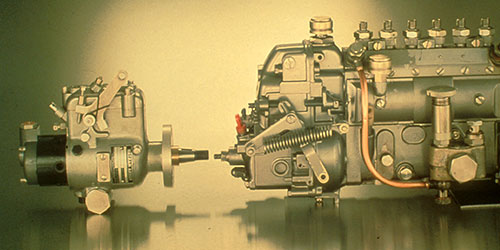

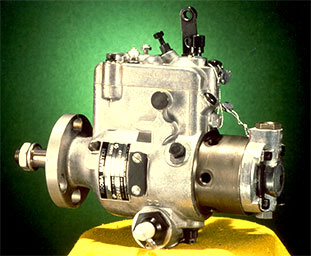

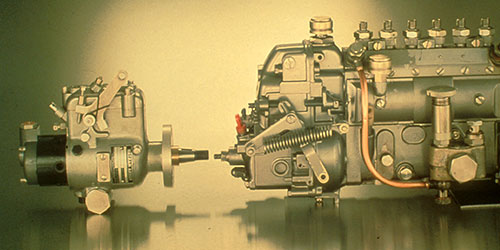

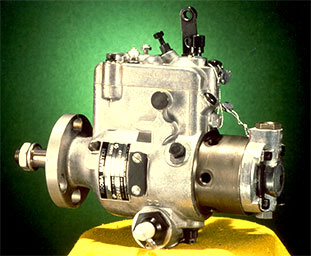

Standard Screw introduces the Roosa Master Injection Pump, the world’s first Diesel Rotary Pump.

1958

Standard Screw builds on its diesel fuel pump line with the introduction of the DB Model Rotary Pump.

1963

Standard Screw develops the Pencil Nozzle Injector, an innovative, compact design that delivers fuel into the center of the cylinder.

1970

Standard Screw becomes Stanadyne, keeping part of its legacy name and drawing off of ‘dynamic’ to progress the image of the company.

1973

Stanadyne introduces the Startmaster, an air starter for large truck applications.

1988

Stanadyne acquires its Brescia, Italy plant to manufacture diesel fuel injectors.

1993

Stanadyne develops the DS Model Rotary Pump, the first electronically governed pump of its kind.

2002

Stanadyne introduces the DE Model Rotary Pump. Stanadyne and the Amalgamations Group agree to a joint venture and open a facility in Chennai, India.

2006

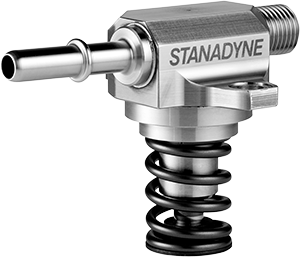

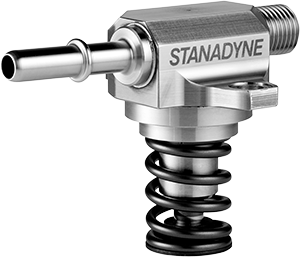

Stanadyne develops the world’s first 200 bar gasoline direct injection pump for the automotive market.

2007

Changshu, China facility opens its doors to engineer and manufacture pumps for Chinese OEMs.

2011

Stanadyne develops a line of Diesel Common Rail Pumps that offered improved fuel efficiency over other market offerings at the time.

2013

Stanadyne enters the high-end racing industry with the highest-capacity gasoline direct injection pump, helping to secure victory in a pivotal race.

today

The 200 Bar gasoline direct injection pump reaches the manufacturing milestone of 1 million units produced. Stanadyne develops the world’s smallest gasoline direct injection pump.

Christopher Spencer invents the automatic screw machine; thus, Hartford Machine Screw Company is born.

To begin building a reputation as a design and engineering focused company, Hartford Machine Screw Company merges with its affiliates to form Standard Screw.

Vernon D. Roosa joins Standard Screw to perfect his design for an on-engine diesel pump.

Standard Screw introduces the Roosa Master Injection Pump, the world’s first Diesel Rotary Pump.

Standard Screw builds on its diesel fuel pump line with the introduction of the DB Model Rotary Pump.

Standard Screw develops the Pencil Nozzle Injector, an innovative, compact design that delivers fuel into the center of the cylinder.

Standard Screw becomes Stanadyne, keeping part of its legacy name and drawing off of ‘dynamic’ to progress the image of the company.

Stanadyne introduces the Startmaster, an air starter for large truck applications.

Stanadyne acquires its Brescia, Italy plant to manufacture diesel fuel injectors.

Stanadyne develops the DS Model Rotary Pump, the first electronically governed pump of its kind.

Stanadyne introduces the DE Model Rotary Pump. Stanadyne and the Amalgamations Group agree to a joint venture and open a facility in Chennai, India.

Stanadyne develops the world’s first 200 bar gasoline direct injection pump for the automotive market.

Changshu, China facility opens its doors to engineer and manufacture pumps for Chinese OEMs.

Stanadyne develops a line of Diesel Common Rail Pumps that offered improved fuel efficiency over other market offerings at the time.

Stanadyne enters the high-end racing industry with the highest-capacity gasoline direct injection pump, helping to secure victory in a pivotal race.

The 200 Bar gasoline direct injection pump reaches the manufacturing milestone of 1 million units produced. Stanadyne develops the world’s smallest gasoline direct injection pump.