Fits in Current Engine Architecture

Scalable for 30 to 1,000-bar fuel systems

The injector’s efficient magnetic design provides excellent feedback for unprecedented fuel control. It significantly reduces over-fueling during the injection-opening event by employing a unique armature solution.

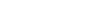

In addition, its variable valve body diameter allows for tighter packaging

and the power group’s modular construction enables fast and efficient changeovers between various connector designs.

Wide Application Range

Efficient Performance

Flexible Design

Unique Features

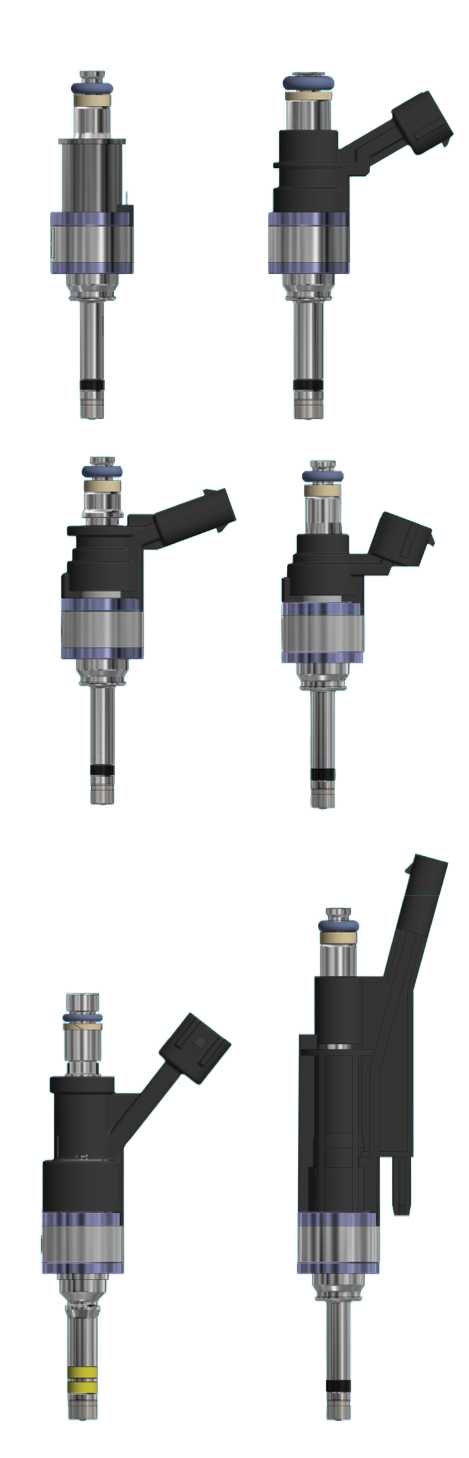

HPDI Injectors

- Efficient magnetic design allows for excellent ballistic control and magnetic feedback

- Armature-stop design reduces over-fueling during the injection opening event

- Valve body diameter meets tighter engine packaging requirements

- The power group’s modular construction enables fast and efficient changeovers between various connector designs

Hover over or click/tap a feature in the list to see it highlighted on the product image!

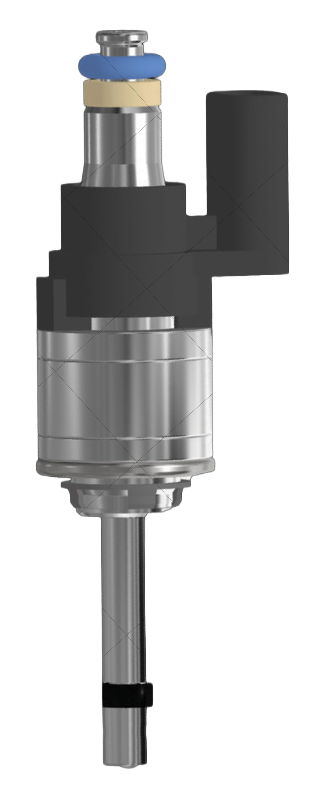

Design & Specifications

GENERAL |

REQUIREMENTS |

|---|---|

| Pmax | Up to 1,000 Bar |

| Operating Pressure | 30 to 1,000 Bar |

| Static Flow @ 100 Bar | Up to 20 g/s |

| Static Flow Tolerance | +/- 4% |

| Dynamic Flow Tolerance | +/- 6% at Ti = 1.5 ms |

| Leakage @ 100 Bar | < 1.5 mm3/min |

| Minimum Time Between Injections | 350 μsec |

| Multiple Injections | 4 |

| MFM Minimum Fuel Mass @ 100 Bar w/n-Heptane | 1.5 mg +/- 15% |

| Spray Angle Single Stream | 8 to 20° |

| Spray Type | Multi hole |

| Overall Spray Angle | 80 to 130° |

| Operating Temperature | -40 to 130 ° C |

| Body Diameter | 21 mm |

| Length | 87 shown, customer driven |

| Tip Diameter | 6 mm |

| Inlet Cup Diameter | 9.4 mm, customer driven |

ELECTRICAL |

REQUIREMENTS |

|---|---|

| Boost Voltage | 65 V |

| Boost time | 480 μs |

| Hold Current | 3.5 A |

| Resistance | 1.5 ohms |

| Supply Voltage | 12-14 V |